Loading... Please wait...

Loading... Please wait...-

Call us at: 941-500-2288

-

Mail Us at: Trains N Scale P.O. Box 178 Lehigh Acres, FL 33970-0178

- My Account

- Items / $0.00

All prices are in All prices are in USD

Categories

- Home

- Models and Prototypes Blog

- A Quick Look: Kato N Gunderson MAXI Stack Car Review

A Quick Look: Kato N Gunderson MAXI Stack Car Review

Posted by Neville C. Wilson on 15th Jun 2021

One of the most popular styles of railcar in contemporary use in North America, currently mainstays on American rails, double stack well cars that are used to transport intermodal containers are some of the most sought-after model railroad products sold today.

With their releases of articulated well car sets, intermodal containers, container handling vehicles, Volvo semi tractor cabs with a container and chassis, Yard Tractors with a container and chassis, and the UNITRAM freight depot sets, which can be used for either automobile, or intermodal terminal facilities, Kato USA markets the most complete intermodal operations system available in N-Scale.

Kato 31-631 Container Handler and 31-617 Volvo Tractor, Container Chassis, and 40 Foot Maersk Container

Kato 31-621 Yard Tractor, Container Chassis, and 40 Foot Cosco Container

Kato 23-142 UNITRAM Freight Depot Basic Set

Over the years, there have been multiple releases of the extremely popular Kato MAXI series intermodal well cars.

With item stock numbers, road names, and road numbers, the Kato USA website has two online pages that are dedicated to all of the N-Scale Gunderson MAXI-I and MAXI-IV sets that have been released thus far.

Comprised of item number 106-6175, a TTX with road number DTTX 724792, speed-line lettering logos, and navy blue CSX Intermodal containers, item number 106-6176, a TTX with road number DTTX 766519, modern red logos, and UMAX containers, item number 106-6177, a Burlington Northern Santa Fe with road number BNSF 253791, circular logos, and green HUB Group containers, item number 106-6178, a Burlington Northern Santa Fe with road number BNSF 253411, swoosh logos, and red HUB Group containers, and item numbers 106-6179 and 106-6180, Pacer Stacktrain units with road numbers BRAN 6020 and BRAN 6066 and Pacer Stacktrain containers, the latest run of Kato N-Scale Gunderson MAXI IV three-unit stack car sets began arriving on dealers shelves in August 2020.

Kato 106-6175 Gunderson MAXI-IV Double Stack Car 3-Unit Set TTX DTTX 724792 with CSX Containers

Kato 106-6176 Gunderson MAXI-IV Double Stack Car 3-Unit Set TTX DTTX 766519 with UMAX Containers

Kato 106-6177 Gunderson MAXI-IV Double Stack Car 3-Unit Set BNSF 253791 with HUB Group Containers

Kato 106-6178 Gunderson MAXI-IV Double Stack Car 3-Unit Set BNSF 253411 with HUB Group Containers

Kato 106-6180 Gunderson MAXI-IV Double Stack Car 3-Unit Set Pacer Stacktrain BRAN 6066 with Containers

Also re-released, comprised of item numbers 106-6194 and 106-6195, Burlington Northern Santa Fe units with road numbers BNSF 238615 and BNSF 238693, swoosh logos, and magenta ONE (Ocean Network Express) containers, item numbers 106-6196 and 106-6197, TTX units with road numbers DTTX 759324 and DTTX 759350, modern red logos, and light gray ONE (Ocean Network Express) containers, and item numbers 106-6198 and 106-6199, MAERSK units with road numbers MAEX 100029 and MAEX 100043 and MAERSK containers, the most recent run Gunderson MAXI-I five-unit sets made their debut in March (MAERSK) and May (BNSF and TTX) 2021.

Kato 106-6194 Gunderson MAXI-I Double Stack Car 5-Unit Set BNSF Swoosh 238615 with ONE Containers

Kato 106-6196 Gunderson MAXI-I Double Stack Car 5-Unit Set TTX DTTX 759324 with ONE Containers

Kato 106-6198 Gunderson MAXI-I Double Stack Car 5-Unit Set Maersk MAEX 100029 with Containers

The MSRP for one of the newest run MAXI-IV sets is $125.00, which is twelve percent higher than the previous MSRP of $110.00 a set.

With a $150.00 MSRP, the pricing on the MAXI-I sets remains unchanged.

Like their predecessors, the recently released models have crisply decorated heavier material steel compound plastic bodies, molded in color plastic brake wheels, hand-grabs, inner well bracing, steps, and walkways, Kato knuckle couplers with end user installed trip pins, and metal wheels that are fitted to steel axles.

Unlike the separately attached injection molded plastic hand-grabs with open see-through centers that are found on the N-Scale Atlas rebuilt intermodal well cars, the centers of the eight plastic hand-grabs found on the ends of the A and B end cars that are shipped with the Kato MAXI I and IV sets are partially filled.

With a flexible clear plastic cover placed over a pocketed gray colored Styrofoam car storage tray that does not retain each car as tightly (i.e., a positive attribute) as some of the earlier versions of packaging did, the sets are shipped in a green cardboard box with three window openings that partially reveal three of the individual units and six of the containers.

Bearing different window arrangements, the latest run of Kato MAXI-I and MAXI IV models are shipped in the same sized box.

Kato 106-6196 Gunderson MAXI-I Double Stack Car 5-Unit Set TTX DTTX 759324 with ONE Containers and Inner and Outer Packaging

One of the big advantages of containerized goods transport is that once they are filled, the contents is not handled again until a container reaches its final destination.

Due to many foreign roadway limitations, twenty and forty foot long shipping containers became the norm for international shipments using a combination of railways, ships, and trucks.

Physical size and cubic capacity are not the only differences between twenty foot and forty foot containers, as their cost, maximum load weight, and usage, also differ.

Shipping containers are designed to carry specific types of cargo based on factors such as weight distribution and weight to volume ratio.

When shipping heavy loads, all of the available space in a container may not be usable.

This is the main reason why twenty foot containers are more suitable for transporting dense commodity items and heavy cargo such as cement, liquids, machinery, metals, and sugar.

Better suited for consumer goods and furniture, with twice the cubic volume of twenty foot containers, forty foot containers do not have twice the maximum load weight capacity.

Contrary to popular belief, because they often require special equipment and handling for loading and typically move more slowly than forty foot containers do, a twenty foot container does not cost half of the price of a forty foot container.

Considerably less cost efficient for less-than-container load (LCL) shipments, in reality, a twenty foot container is roughly 75% of the cost of a forty foot container.

As railways typically require that twenty foot containers travel in pairs, many carriers have been phasing them out, or discouraging their customers from using them.

With load bearing points located on their ends, forty foot containers are the standard unit length.

While both container heights are eight foot wide, in contrast to standard (which are also called low-cube or LC) containers, which have a maximum height of eight foot six inches, high-cube (which are also called hi-cube or HC) models stand nine foot six inches tall.

To accommodate bigger or taller items, a shipper may choose a high cube container.

Although twenty foot long containers cannot be stacked upon a longer length container, with their excess length hanging equally over each end of the smaller container that they have been perched upon, longer length containers are designed with centrally located load bearing points that are positioned forty foot apart.

Eventually becoming the Marine and Rail Equipment Division (MRED) of FMC in 1973, FMC Corporation acquired the Gunderson Bros. Engineering Corporation in 1965.

A joint venture with Greenbrier saw the 1984 introduction of the five-unit Gunderson Twin-Stack® articulated well cars with bulkheads.

In 1985,

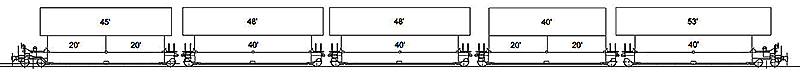

While a forty-five foot long shipping container could be loaded on top of a forty footer that was placed in the well, designed to provide support for stacked containers, which at the time, lacked the rotating Inter-box Connectors (IBC's) that are currently used to secure the boxes when they were moved, stowed, or in transit, the bulkheads prevented the top loading of forty-eight and fifty-three footers.

Greenbrier Gunderson Twin-Stack® Promotional Images Courtesy of The Greenbrier Companies

The advent of forty-eight foot long domestic intermodal containers saw the need for a new articulated well car design that eliminated the problematic bulkheads.

In 1989, Greenbrier Gunderson introduced the five-unit MAXI-Stack® III, which could accommodate twenty to forty-eight foot long containers in their wells, with forty to fifty-three footers stacked on top.

Once they could be legally transported on the majority of US highways, fifty-three foot long containers became a standard for domestic North American cartage, which resulted in the development of the ubiquitous MAXI-Stack® IV.

Although roadway regulations vary by state, with previously established height and width limits that have for the most part remained in place (i.e., except for the domestic fifty-three foot long high cube containers which are nine foot six inches high and eight foot six inches wide), increases in domestic container load weight and size were derived from the common maximum legal length and fully loaded weight of fifty-three foot for semi-tractor trailers.

Due to the size and weight of the fully loaded containers that they were designed to carry, the MAXI-Stack® IV is confined to a three-unit length.

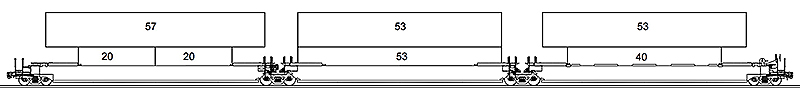

MAXI-Stack® IV Container Loading Examples Diagram Courtesy of The Greenbrier Companies

On a production hiatus throughout the 1990s, owing to a huge rise in international ISO container transportation and increased demands from railroads, with a large order initially placed by the BNSF Railway, the production of revised MAXI-Stack® I sets resumed in 2000.

According to an April 16, 2020 press release, due to the economic

impacts of COVID-19, The Greenbrier Companies, Inc. had suspended the

production of new railcars at its flagship Greenbrier Gunderson manufacturing

facility in

Run continuously for nearly twenty-five years, attributed to corporate cost cutting measures, weak customer demand, and waning intermodal rail loadings which were exacerbated by the effects of the COVID-19 outbreak, during the previous week, Greenbrier Gunderson ended the production of its double stack car line.

The now defunct Deluxe Innovations previously released factory assembled N-Scale models of the Twin Stack®, MAXI-Stack® III, and MAXI-Stack® IV (i.e., an earlier production version) articulated well cars.

Deluxe Innovations Twin-Stack® TTX DTTX 63299 "A" End and "E" Mid Cars

Deluxe Innovations Twin-Stack® Santa Fe Econo-Stack SFLC 254003 "A"End Car

Deluxe Innovations MAXI-Stack® III American President Lines (APL) and Trailer Train "D" and "E" Mid Cars

Deluxe Innovations MAXI-Stack® IV TTX DTTX 726750 "A" End and "C" Mid Cars

To date, the Kato MAXI I is the only available ready-to-run N-Scale model of the now ubiquitous five-unit Greenbrier Gunderson well car sets.

Providing an optimum balance between tare weight, load capacity, and railcar slack action, designed for railroads that transport large numbers of international ISO containers that are used for overseas shipments, with a forty to fifty-three foot long container loaded on top, the wells on a MAXI-Stack® I can accommodate a forty footer, or a pair twenty footers.

MAXI-Stack® I Container Loading Examples Diagram Courtesy of The Greenbrier Companies

In some parts of

Although the use of

smaller wheel sizes lowers a railway car's carrying capacity, in order to

reduce the vertical clearance needed for railway operation, in

Compared to other types of rolling-stock that are primarily constructed out of steel, even when they are fully loaded, autorack cars have fairly light axle loads.

This is not the case with the Greenbrier Gunderson MAXI series cars, which for load bearing reasons (i.e., the bulk of the load weight is borne by the mid-car trucks and wheels) have trucks with two different load capacities, that are fitted with two different wheel sizes

Like the prototype car sets, the Kato models have thirty-six inch wheels on the coupler equipped 70-ton end car trucks and thirty-eight inch wheels on the 125-ton mid-car trucks.

Kato 800112 125-Ton MAXI-Stack® Mid-Car Truck without Coupler

When they were checked with a Micro-Trains® Line height gauge, the truck mounted Kato magnetic knuckle couplers were found to be at the correct height.

Using an NMRA Standards Gauge, the wheel-sets were found to be properly gauged.

As the wheels have low-profile flanges, when they were run on Atlas Code 55 track, no tracking issues were noticed.

Bearing the letters A through E, there is a specific order in which the MAXI-I car bodies must be assembled.

The A and B units are end cars and the C through E units are mid-cars

Starting with the A unit and ending with the B unit, the middle cars are attached in descending order (i.e., E, D, and C).

Kato Gunderson MAXI-I Double Stack Car Connection Order Diagram Courtesy Kato USA

Joined in the same manner and bearing the same lettering scheme as the MAXI-I cars, the MAXI-IV mid car has the letter C and the end cars bear the letters A and B.

Kato Gunderson MAXI-IV Double Stack Car Connection Order Diagram Courtesy Kato USA

Absent on the MAXI-IV cars, like the prototype, which has circular depressions on the inner faces of the well sides, there are twelve circular cut-outs molded into each side of the injection molded plastic interior support frames of the Kato MAXI-I wells.

Given that the weight of articulated car sets was never factored into the National Model Railroad Association's NMRA RP-20.1 recommended practice guidelines for rolling-stock weight, it is somewhat difficult to determine if the Kato car sets are too light, too heavy, or just right.

With an individual car body length of 4.1875 inches, a fully assembled length of 20.0 inches without the couplers, a weight of 2.2 ounces empty, and 4.4 ounces with a full complement of Kato forty foot containers, with a pair of trucks attached, each of the five units that a MAXI-I set is comprised of weighs 0.4 of an ounce empty and 1.0 ounce with a pair of factory supplied containers.

On an individual unit basis, loaded with a pair of forty-foot containers and fitted with a pair of trucks, each MAXI-I well is 0.15 of an once lighter than NMRA RP-20.1 recommended weight of 1.15 ounces.

With individual car body length of 5.125 inches, a fully assembled length of 15.25 inches without the couplers, a weight of 1.8 ounces empty, and 3.6 ounces with a full complement of Kato fifty-three foot containers, with a pair of trucks attached, each of the three units that a MAXI-IV set is comprised of weighs 0.6 of an ounce empty and 1.2 ounces with a pair of factory supplied containers.

On an individual unit basis, loaded with a pair of fifty-three foot containers and fitted with a pair of trucks, each MAXI-IV well is 0.10 of an once lighter than NMRA RP-20.1 recommended weight of 1.30 ounces.

Negligible in both cases, if the minor weight discrepancies are a major concern, end users can add some weight to the loaded containers.

Somewhat off, both models have plastic detail parts that are molded in color, rather than painted like the rest of the car body is.

Molded in silver plastic, with a thickness that varies from approximately 0.20 to 0.28 of an inch, the models' walkways are not see-through.

Despite the sets' continued popularity, no aftermarket etched metal hand-grabs and/or walkway detail kits are available for either of the Kato models.

As railroads consider multi-unit articulated well car sets like the Greenbrier Gunderson MAXI series models to be a single car, an entire consist shares the same road number.

Kato 23-507B 40 Foot Intermodal Container K-Line KLFU 988962

The latest run of MAXI-I sets were shipped with the following forty foot container liveries and serial/registration numbers:

Kato Item Number 106-6194 has ten (magenta) One (Ocean Network Express) ONEU 000014 containers

Kato Item Number 106-6195 has ten (magenta) One (Ocean Network Express) ONEU 000255 containers

Kato Item Number 106-6196 has ten (light gray) One (Ocean Network Express) ONEU 002277 containers

Kato Item Number 106-6197 has ten (light gray) One (Ocean Network Express) ONEU 002289 containers

Kato Item Number 106-6198 has ten Maersk MSKU 585 436 42G1 containers

Kato Item Number 106-6199 has ten Maersk MSKU 620 436 42G1 containers

Kato 800546 53 Foot Intermodal Container Pacer Stacktrain PACU 880360

The latest run of MAXI-IV sets were shipped with the following fifty-three foot container liveries and serial/registration numbers:

Kato Item Number 106-6175 has six CSX Intermodal CSXU 633827 containers

Kato Item Number 106-6176 has six UMAX UMXU 246222 containers

Kato Item Number 106-6177 has six (green) Hub Group UPHU 249466 containers

Kato Item Number 106-6178 has six (red) Hub Group HGIU 635664 containers

Kato Item Number 106-6179 has six Pacer Stacktrain PACU 885404 containers

Kato Item Number 106-6180 has six Pacer Stacktrain PACU 895418 containers

Firmly held in place by a factory installed magnet and metal plate when they are stacked or placed in a metal bodied well car, the Kato forty and fifty-three foot containers are completely interchangeable.

The MAXI-I comes with ten forty foot containers and the MAXI-IV is shipped with six fifty-three footers.

With their factory installed metal plate and magnet, both container lengths weigh 0.2 of an ounce.

Despite the installation of the injection molded plastic inner well bracing, the steel compound plastic that was used to fabricate the car bodies allows containers with magnets in their bottoms to remain in place during car operation.

In fact, a scene (i.e., time frame 1:18 to 1:20) in a 2012 Kato produced YouTube video shows a single MAXI-IV unit briefly held upside down, with a pair of fifty-three foot long containers still locked in place in the well.

Athearn (twenty and forty footers), Atlas (forty footers), Deluxe Innovations/Fox Valley (twenty and forty footers), Jacksonville Terminal Company (JTC twenty and forty footers), Rolland (twenty and forty footers), and Walthers (forty footers) containers will fit in a Kato MAXI-I well.

Deluxe Innovations (i.e., a bit snugly), Jacksonville Terminal Company (i.e., although the JTC pins do not line up with the rectangular retention slots that are located in the bottom of the well's inner brace casting), Micro-Trains® Line, and ScaleTrains fifty-three foot containers will fit into a Kato MAXI-IV well.

Although the pins on Atlas fifty-three footers will line up with the rectangular retention slots found in the Maxi-IV wells, the containers' raised door detail prevents them from being used without modifying the ends of the Kato models plastic inner brace casting.

A tad bit longer than the comparable Kato version, as is the case with the aforementioned Atlas fifty-three foot long products, while their pins line up with the slots, the Athearn CIMC fifty-three foot containers will not fit into the Maxi-IV wells without some end-user alterations.

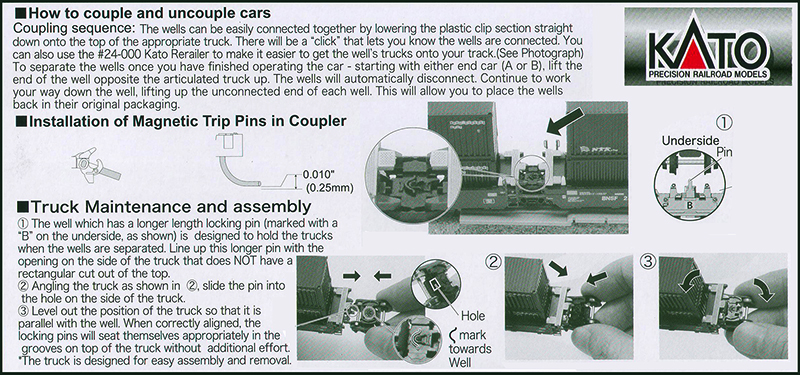

While not as easy to set up as the Deluxe Innovations cars are, the same on both of the Kato MAXI sets, providing secure and reliable connections, four pins and a pair of lower supports retain adjoining units to a 125-ton truck.

Once you become familiar with Kato's unique design, linking and unlinking the individual cars becomes less troublesome.

Kato Gunderson MAXI Double Stack Car User Instructions Courtesy Kato USA

Along with the user instructions that are printed on the backs of the cardboard boxes that the sets are packed in, Kato has a instructional YouTube video that explains the entire connection process.

Unlike the very finely detailed Deluxe Innovations early version MAXI-IV sets, which were first shipped to dealers in February 2015, have end-user installed mud flaps for the A and B car platform ends, see-through etched stainless steel lift rings and walkways, and a twelve-inch to fourteen-inch (i.e., with the mud flaps attached) minimum operating radius, with their Atlas code 55 track friendly wheels, both of the Kato models negotiate eleven-inch radius curves, crossover tracks, and turnouts with ease.

Deluxe Innovations 350101 MAXI-Stack® IV TTX DTTX 723210

Per prototype railway practices, where lighter pieces of rolling-stock are typically placed toward the rear of a train consist, given their typically light weight, it would probably be prudent to place your empty well car models on the end of a train.

As is case with moves to and from train club layouts, and/or NTRAK, and/or T-TRAK gatherings, somewhat harder to assemble and disassemble when they are compared to their single unit counterparts, with their robust detailing (i.e., as opposed to many of the competitive intermodal well car models that are produced by other manufacturers), the Kato products are better suited for situations that require frequent handling.

While purists might bemoan the fact that Kato chose to use unpainted and somewhat off-color plastic detail parts and well interior support frames, end-car hand grabs with partially filled centers, and thick plastic walkways that are devoid of see-through holes, most buyers will find that the durably fabricated Kato models make excellent additions to an intermodal car fleet.

View additional articles like this one in the Trains N Scale™ Models and Prototypes Blog.

Recent Posts

- » A Quick Look: InterMountain Fox Valley Red Caboose Autoracks Review

- » A Quick Look: Athearn 2293 N UPS Wedge Trailers and Dolly

- » A Quick Look: Atlas N 1993 Ford Explorer SUV 5th Run Review

- » A Quick Look: Eastern Seaboard Models N Metal Wheel-Sets Review

- » A Quick Look: Jacksonville Terminal JTC NSC 53' Well Cars Review